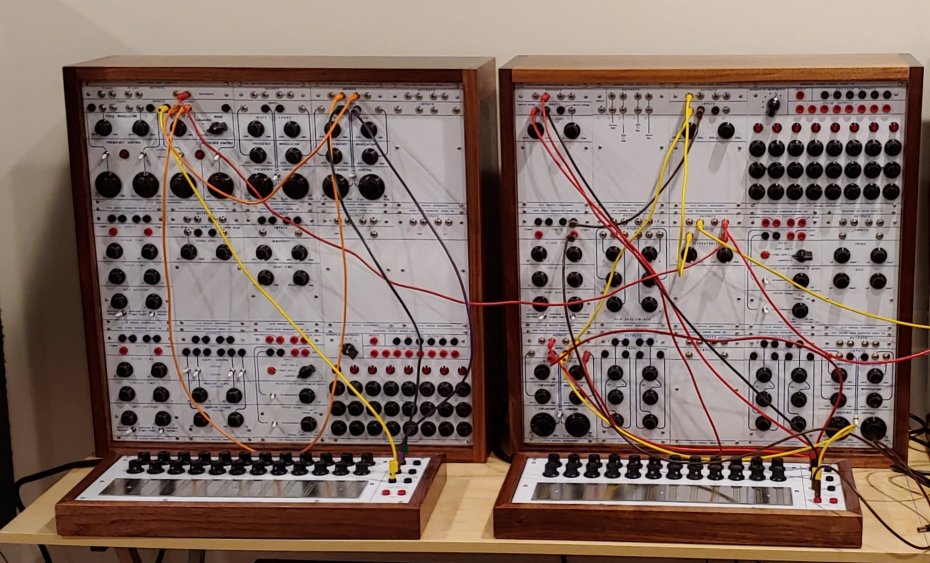

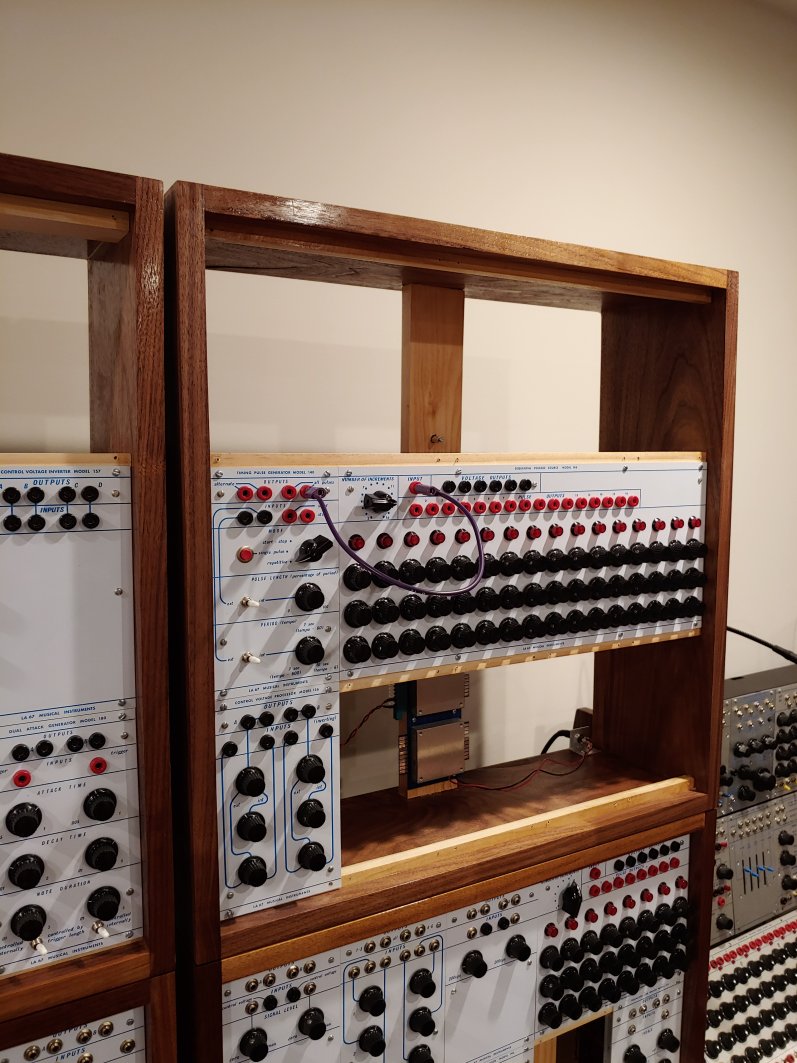

I decided to build the early Buchla style cabinets and boats made from black walnut. The wood I used was 1" thick and a tad over 8" wide for the cabinets. I didn't miter the back and side joints of the cabinets like the pictures I've seen of 1960's Buchlas, as I felt the joints wouldn't be as strong, and more prone to damage on the corners.

(click on the pictures for a larger view)

I did miter the joints on the boats, though. I selected a 10 foot 1" x 4" black walnut plank for the boats, which the kind folks at Exotic Hardwoods in Annapolis ripped exactly in half for me, so the boats are about 1.75" high. I had an old piece of 5mm plywood that I used for the bottom. The thin foam-rubber pads seend here are also on the bottoms of the cabinets. They are just thick enough that none of the bare wood touches when I stack the cabinets.

There is a hole in the back of the boat, 2" from the left end, for the power cable. I made nice long covered cables with DB15 connectors on the end, to mate with a DB15 socket in back of the cabinets. I also put DB15 connectors in the front of my BEMI 24 space cabinets.

The black foot pads you see are Everbilt 1-1/2in Anti-Skid Pads, which I bought at Home Depot. I used these on the cabinets as well. They are self-stick, and thin enough that you don't see a huge gap underneath, but thick enough to protect the wood. See the picture of the stacked cabinets at the bottom of this page.

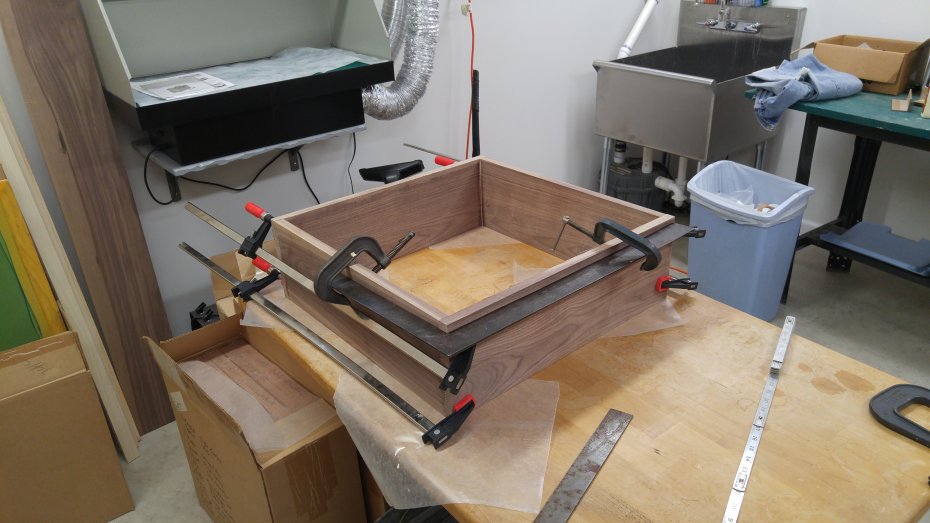

Initial glueing and clamping a cabinet. The black carpenters square is used to ensure that the whole thing remains square. It's a nineteenth century square hand made by a blacksmith that was used by my grandfather back in Illinois.

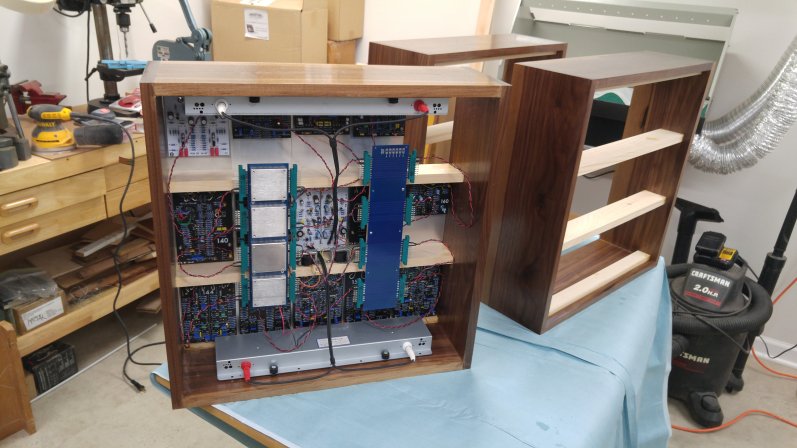

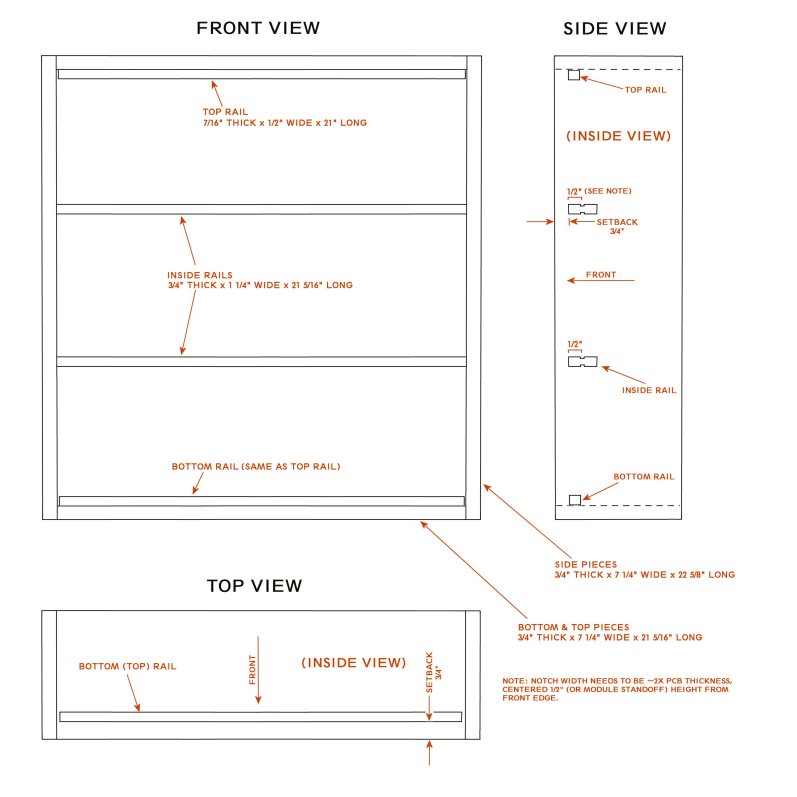

Glueing up the mounting rails. The rails are white pine (middle rails) and poplar (top and bottom). I cut the rails to length at the same time as the top and bottom cabinet pieces, so that they're all exactly the same length. Getting the rails into the cabinets was a little tricky because of the close fit. They were tight enough that I almost didn't need to use clamps. I laid modules on the rails in the top, middle and bottom rows, and slid them back and forth to make sure the 2 middle rails were spaced properly. I Marked their positions carefully, and glued them up.

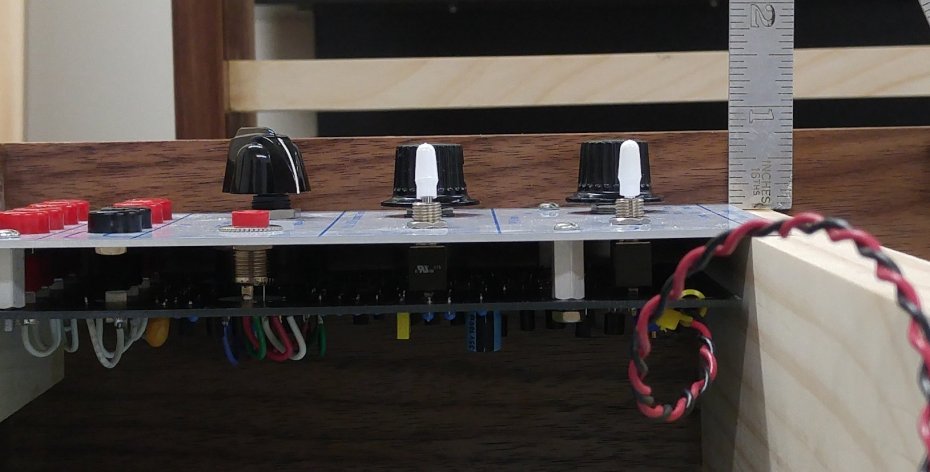

Looking sideways at the setback of the module mounting rails from the front edge of the cabinet. I allowed 3/4", thinking that this would keep all of the knobs from protruding, in case I ever wanted to lay the cabinet face down (and not have the knobs bearing the weight of the cabinet). Turns out that 7/8" or more would have been needed, because of the height of the larger skirted knobs. The chicken-head knob shown here is on a shaft that needs to be trimmed a little, so it's not a problem. Oh well, I've never had the need to lay any other cabinet face down anyway.

Woodworking is done! 2-3 coats of oil-base Polyeurethane varnish after a LOT of sanding. The 1st cabinet is wired up with a buss board from Boops, with all 4 Cincon DC-DC converters with +/-15, +5, +12 and +24 Volts available. The +24 Volts is on pin 10, which is normally not used in the Buchla world. I didn't worry about the I2C lines, but otherwise any generation of Buchla modules are provided for. The module in the very center is the 190 Reverberation - you can see the 2 transformers mounted on the rail between the buss boards. The tanks are mounted at the top and bottom. I later put a DB15 connector on a bracket at the bottom, to supply all of the voltages via cable to the boats.